There’s a tendency in our industry to talk about “small molecules versus biologics” as if we woke up one morning and the world had simply divided itself into two neat categories. But the truth is more interesting—and more instructive—than that. The dividing line was drawn by one molecule in particular: insulin. And the story of how insulin moved from animal extraction to recombinant manufacturing didn’t just change how we make one drug. It fundamentally rewired how we think about manufacturing, quality, and regulation across the entire pharmaceutical landscape.

From Pancreases to Plasmids

For the first six decades of its therapeutic life, insulin was an extractive product. Since the 1920s, producing insulin required enormous quantities of animal pancreases—primarily from cows and pigs—sourced from slaughterhouses. Eli Lilly began full-scale animal insulin production in 1923 using isoelectric precipitation to separate and purify the hormone, and that basic approach held for decades. Chromatographic advancements in the 1970s improved purity and reduced the immunogenic reactions that had long plagued patients, but the fundamental dependency on animal tissue remained.

This was, in manufacturing terms, essentially a small-molecule mindset applied to a protein. You sourced your raw material, you extracted, you purified, you tested the final product against a specification, and you released it. The process was relatively well-characterized and reproducible. Quality lived primarily in the finished product testing.

But this model was fragile. Market forces and growing global demand revealed the unsustainable nature of dependency on animal sources. The fear of supply shortages was real. And it was into this gap that recombinant DNA technology arrived.

1982: The Paradigm Breaks Open

In 1978, scientists at City of Hope and Genentech developed a method for producing biosynthetic human insulin (BHI) using recombinant DNA technology, synthesizing the insulin A and B chains separately in E. coli. On October 28, 1982, after only five months of review, the FDA approved Humulin—the first biosynthetic human insulin and the first approved medical product of any kind derived from recombinant DNA technology.

Think about what happened here. Overnight, insulin manufacturing went from:

- Animal tissue extraction → Living cell factory production

- Sourcing variability tied to agricultural supply chains → Engineered biological systems with defined genetic constructs

- Purification of a natural mixture → Directed expression of a specific gene product

The production systems themselves tell the story. Recombinant human insulin is produced predominantly in E. coli (where insulin precursors form inclusion bodies requiring solubilization and refolding) or in Saccharomyces cerevisiae (where soluble precursors are secreted into culture supernatant). Each system brings its own manufacturing challenges—post-translational modification limitations in bacteria, glycosylation considerations in yeast—that simply did not exist in the old extraction paradigm.

This wasn’t just a change in sourcing. It was a change in manufacturing identity.

“The Process Is the Product”

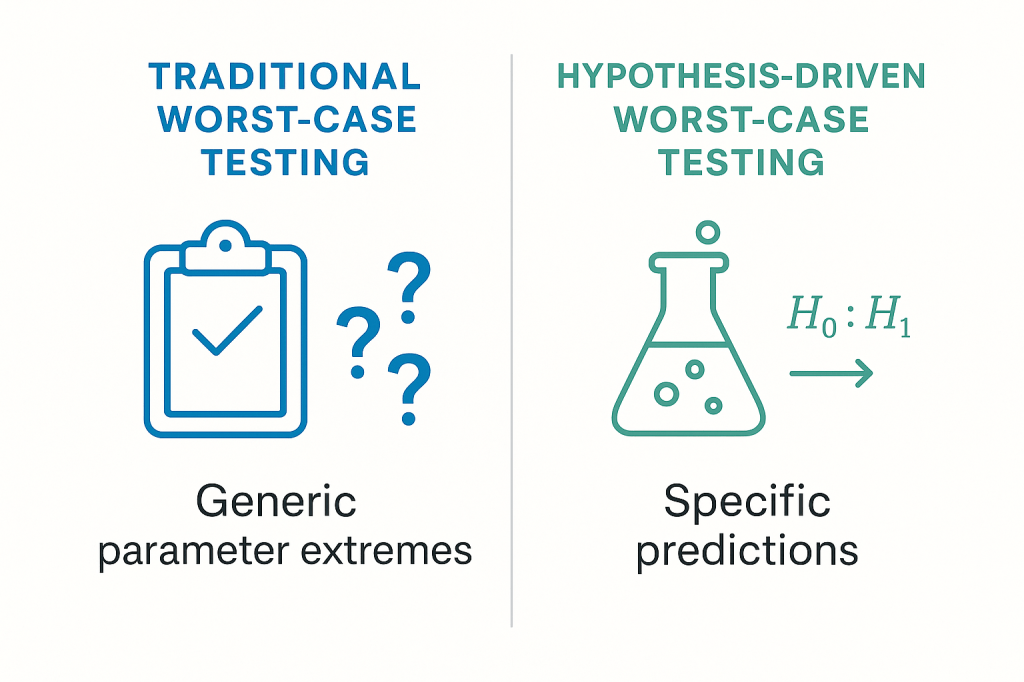

And here is where the real conceptual earthquake happened. With small-molecule drugs, you can fully characterize the molecule. You know every atom, every bond. If two manufacturers produce the same compound by different routes, you can prove equivalence through analytical testing of the finished product. The process matters, but it isn’t definitional.

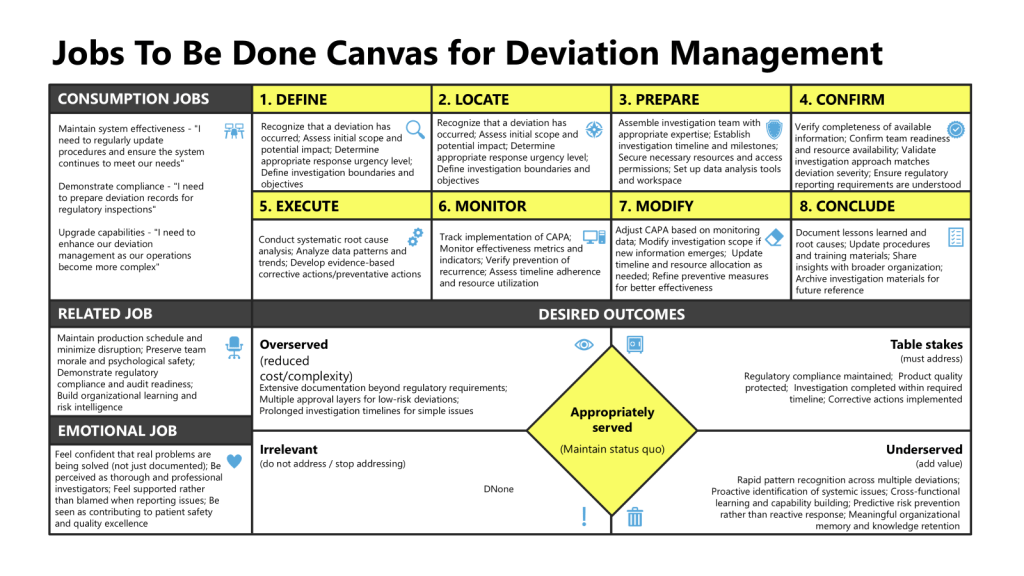

Biologics are different. As the NIH Regulatory Knowledge Guide puts it directly: “the process is the product”—any changes in the manufacturing process can result in a fundamental change to the biological molecule, impacting the product and its performance, safety, or efficacy. The manufacturing process for biologics—from cell bank to fermentation to purification to formulation—determines the quality of the product in ways that cannot be fully captured by end-product testing alone.

Insulin was the first product to force the industry to confront this reality at commercial scale. When Lilly and Genentech brought Humulin to market, they weren’t just scaling up a chemical reaction. They were scaling up a living system, with all the inherent variability that implies—batch-to-batch differences in cell growth, protein folding, post-translational modifications, and impurity profiles.

This single insight—that for biologics, process control is product control—cascaded through the entire regulatory and quality framework over the next four decades.

The Regulatory Framework Catches Up

Insulin’s journey also exposed a peculiar regulatory gap. Despite being a biologic by any scientific definition, insulin was regulated as a drug under Section 505 of the Federal Food, Drug, and Cosmetic Act (FFDCA), not as a biologic under the Public Health Service Act (PHSA). This was largely a historical accident: when recombinant insulin arrived in 1982, the distinctions between FFDCA and PHSA weren’t particularly consequential, and the relevant FDA expertise happened to reside in the drug review division.

But this classification mismatch had real consequences. Because insulin was regulated as a “drug,” there was no pathway for biosimilar insulins—even after the Hatch-Waxman Act of 1984 created abbreviated pathways for generic small-molecule drugs. The “generic” framework simply doesn’t work for complex biological molecules where “identical” is the wrong standard.

It took decades to resolve this. The Biologics Price Competition and Innovation Act (BPCIA), enacted in 2010 as part of the Affordable Care Act, created an abbreviated regulatory pathway for biosimilars and mandated that insulin—along with certain other protein products—would transition from drug status to biologic status. On March 23, 2020, all insulin products were formally “deemed to be” biologics, licensed under Section 351 of the PHSA.

This wasn’t a relabeling exercise. It opened insulin to the biosimilar pathway for the first time, culminating in the July 2021 approval of Semglee (insulin glargine-yfgn) as the first interchangeable biosimilar insulin product. That approval—allowing pharmacy-level substitution of a biologic—was a moment the industry had been building toward for decades.

ICH Q5 and the Quality Architecture for Biologics

The regulatory thinking that insulin forced into existence didn’t stay confined to insulin. It spawned an entire framework of ICH guidelines specifically addressing the quality of biotechnological products:

- ICH Q5A – Viral safety evaluation of biotech products derived from cell lines

- ICH Q5B – Analysis of the expression construct in cell lines

- ICH Q5C – Stability testing of biotechnological/biological products

- ICH Q5D – Derivation and characterization of cell substrates

- ICH Q5E – Comparability of biotechnological/biological products subject to changes in their manufacturing process

ICH Q5E deserves particular attention because it codifies the “process is the product” principle into an operational framework. It states that changes to manufacturing processes are “normal and expected” but insists that manufacturers demonstrate comparability—proving that post-change product has “highly similar quality attributes” and that no adverse impact on safety or efficacy has occurred. The guideline explicitly acknowledges that even “minor” changes can have unpredictable impacts on quality, safety, and efficacy.

This is fundamentally different from the small-molecule world, where a process change can often be managed through updated specifications and finished-product testing. For biologics, comparability exercises can involve extensive analytical characterization, in-process testing, stability studies, and potentially nonclinical or clinical assessments.

How This Changed Industry Thinking

The ripple effects of insulin’s transition from extraction to biologics manufacturing reshaped the entire pharmaceutical industry in several concrete ways:

1. Process Development Became a Core Competency, Not a Support Function.

When “the process is the product,” process development scientists aren’t just optimizing yield—they’re defining the drug. The extensive process characterization, design space definition, and control strategy work enshrined in ICH Q8 (Pharmaceutical Development) and ICH Q11 (Development and Manufacture of Drug Substances) grew directly from the recognition that biologics manufacturing demands a fundamentally deeper understanding of process-product relationships.

2. Cell Banks Became the Crown Jewels.

The master cell bank concept—maintaining a characterized, qualified starting point for all future production—became the foundational control strategy for biologics. Every batch traces back to a defined, banked cell line. This was a completely new paradigm compared to sourcing animal pancreases from slaughterhouses.

3. Comparability Became a Lifecycle Discipline.

In the small-molecule world, process changes are managed through supplements and updated batch records. In biologics, every significant process change triggers a comparability exercise that can take months and cost millions. This has made change control for biologics a far more rigorous discipline and has elevated the role of quality and regulatory functions in manufacturing decisions.

4. The Biosimilar Paradigm Created New Quality Standards.

Unlike generics, biosimilars cannot be “identical” to the reference product. The FDA requires a demonstration that the biosimilar is “highly similar” with “no clinically meaningful differences” in safety, purity, and potency. This “totality of evidence” approach, developed for the BPCIA pathway, requires sophisticated analytical, functional, and clinical comparisons that go well beyond the bioequivalence studies used for generic drugs.

5. Manufacturing Cost and Complexity Became Strategic Variables.

Biologics manufacturing requires living cell systems, specialized bioreactors, extensive purification trains (including viral clearance steps), and facility designs with stringent contamination controls. The average cost to develop an approved biologic is estimated at $2.6–2.8 billion, compared to significantly lower costs for small molecules. This manufacturing complexity has driven the growth of the CDMO industry and made facility design, tech transfer, and manufacturing strategy central to business planning.

The Broader Industry Shift

Insulin was the leading edge of a massive transformation. By 2023, the global pharmaceutical market was $1.34 trillion, with biologics representing 42% of sales (up from 31% in 2018) and growing three times faster than small molecules. Some analysts predict biologics will outstrip small molecule sales by 2027.

This growth has been enabled by the manufacturing and regulatory infrastructure that insulin’s transition helped build. The expression systems first commercialized for insulin—E. coli and yeast—remain workhorses, while mammalian cell lines (especially CHO cells) now dominate monoclonal antibody production. The quality frameworks (ICH Q5 series, Q6B specifications, Q8–Q11 development and manufacturing guidelines) provide the regulatory architecture that makes all of this possible.

Even the regulatory structure itself—the distinction between 21 CFR Parts 210/211 (drug CGMP) and 21 CFR Parts 600–680 (biologics)—reflects this historical evolution. Biologics manufacturers must often comply with both frameworks simultaneously, maintaining drug CGMP baselines while layering on biologics-specific controls for establishment licensing, lot release, and biological product deviation reporting.

Where We Are Now

Today, insulin sits at a fascinating intersection. It’s a relatively small, well-characterized protein—analytically simpler than a monoclonal antibody—but it carries the full regulatory weight of a biologic. The USP maintains five drug substance monographs and thirteen drug product monographs for insulin. Manufacturers must hold Biologics License Applications, comply with CGMP for both drugs and biologics, and submit to pre-approval inspections.

Meanwhile, the manufacturing technology continues to evolve. Animal-free recombinant insulin is now a critical component of cell culture media used in the production of other biologics, supporting CHO cell growth in monoclonal antibody manufacturing—a kind of recursive loop where the first recombinant biologic enables the manufacture of subsequent generations.

And the biosimilar pathway that insulin’s reclassification finally opened is beginning to deliver on its promise. Multiple biosimilar and interchangeable insulin products are now reaching patients at lower costs. The framework developed for insulin biosimilars is being applied across the biologics landscape—from adalimumab to trastuzumab to bevacizumab.

The Lesson for Quality Professionals

If there’s a single takeaway from insulin’s manufacturing evolution, it’s this: the way we make a drug is inseparable from what the drug is. This was always true for biologics, but it took insulin—the first recombinant product to reach commercial scale—to force the industry and regulators to internalize that principle.

Every comparability study you run, every cell bank qualification you perform, every process validation protocol you execute for a biologic product exists because of the conceptual framework that insulin’s journey established. The ICH Q5E comparability exercise, the Q5D cell substrate characterization, the Q5A viral safety evaluation—these aren’t bureaucratic requirements imposed from outside. They’re the rational response to a fundamental truth about biological manufacturing that insulin made impossible to ignore.

The molecule that changed everything didn’t just save millions of lives. It rewired how an entire industry thinks about the relationship between process and product. And in doing so, it set the stage for every biologic that followed.