Among the most enduring tools of root cause analysis are the M-based frameworks, which categorize contributing factors to problems using mnemonic classifications. These frameworks have evolved significantly over decades, expanding from the foundational 4M Analysis to more comprehensive models like 5M, 6M, and even 8M. This progression reflects the growing complexity of industrial processes, the need for granular problem-solving, and the integration of human and systemic factors into quality control.

Origins of the 4M Framework

The 4M Analysis emerged in the mid-20th century as part of Japan’s post-war industrial resurgence. Developed by Kaoru Ishikawa, a pioneer in quality management, the framework was initially embedded within the Fishbone Diagram (Ishikawa Diagram), a visual tool for identifying causes of defects. The original four categories—Manpower, Machine, Material, and Method—provided a structured approach to dissecting production issues.

Key Components of 4M

- Manpower: Human factors such as training, skill gaps, and communication.

- Machine: Equipment reliability, maintenance, and technological limitations.

- Material: Quality and suitability of raw materials or components.

- Method: Procedural inefficiencies, outdated workflows, or unclear standards.

This framework became integral to Total Productive Maintenance (TPM) and lean manufacturing, where it was used to systematically reduce variation and defects.

However, the 4M model had limitations. It often overlooked external environmental factors and measurement systems, which became critical as industries adopted stricter quality benchmarks.

Expansion to 5M and 5M+E

To address these gaps, the 5M Model introduced Measurement as a fifth category, recognizing that inaccurate data collection or calibration errors could skew process outcomes. For instance, in pharmaceutical production, deviations in process weight might stem from faulty scales (Measurement) rather than the raw materials themselves.

Concurrently, the 5M+E variant added Environment (or Milieu) to account for external conditions such as temperature, humidity, or regulatory changes. This was particularly relevant in industries like food processing, where storage conditions directly impact product safety. The 5M+E framework thus became a staple in sectors requiring rigorous environmental controls.

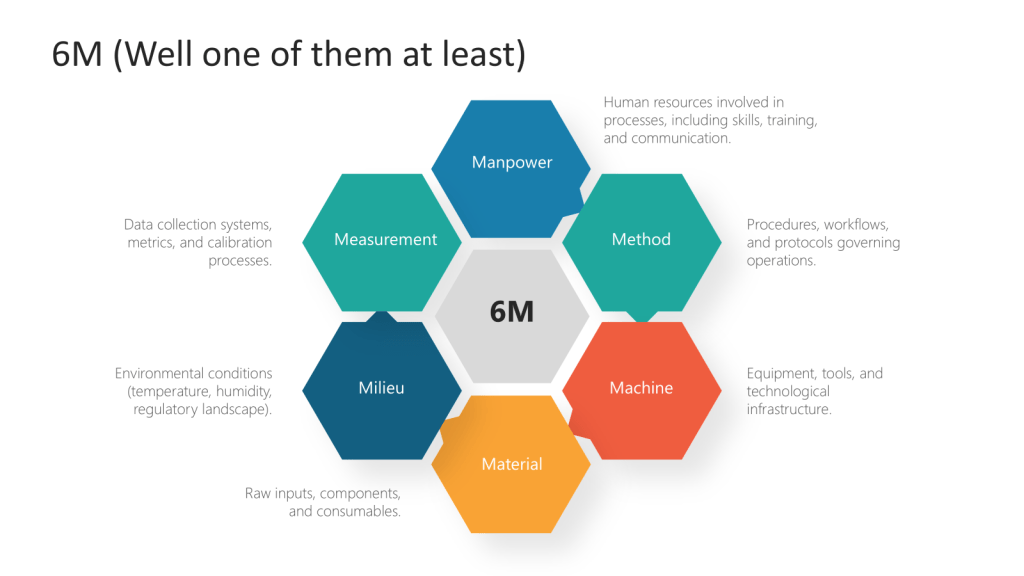

The Rise of 6M and Specialized Variations

The 6M model addresses gaps in earlier iterations like the 4M framework by formalizing measurement and environmental factors as core variables. For instance, while the original 4M (Man, Machine, Material, Method) focused on internal production factors, the expanded 6M accounts for external influences like regulatory changes (Milieu) and data integrity (Measurement). This aligns with modern quality standards such as ISO 9001:2015, which emphasizes context-aware management systems.

Other versions of 6M Model further expanded the framework by incorporating Mother Nature (environmental factors) or Maintenance, depending on the industry. In agriculture, for instance, crop yield variations could be linked to drought (Mother Nature), while in manufacturing, machine downtime might trace to poor maintenance schedules.

| M Factor | Description | Key Insights |

|---|---|---|

| Manpower | Human resources involved in processes, including skills, training, and communication | – Skill gaps or inadequate training directly impact error rates – Poor communication hierarchies exacerbate operational inefficiencies – Workforce diversity and engagement improve problem-solving agility |

| Method | Procedures, workflows, and protocols governing operations | – Outdated methods create bottlenecks – Overly rigid procedures stifle innovation – Standardized workflows reduce process variation by 30-50% |

| Machine | Equipment, tools, and technological infrastructure | – Uncalibrated machinery accounts for 23% of manufacturing defects – Predictive maintenance reduces downtime by 40% – Aging equipment increases energy costs by 15-20% |

| Material | Raw inputs, components, and consumables | – Supplier quality variances cause 18% of production rework – Material traceability systems reduce recall risks by 65% |

| Milieu | Environmental conditions (temperature, humidity, regulatory landscape) | – Temperature fluctuations alter material properties in 37% of pharma cases – OSHA compliance reduces workplace accidents by 52% – Climate-controlled storage extends food product shelf life by 30% |

| Measurement | Data collection systems, metrics, and calibration processes | – Uncalibrated sensors create 12% margin of error in aerospace measurements – Real-time data analytics improve defect detection rates by 44% – KPIs aligned with strategic goals increase operational transparency |

Industry-Specific Adaptations

- Healthcare: Adapted 6Ms include Medication, Metrics, and Milieu to address patient safety.

- Software Development: Categories like Markets and Money are added to analyze project failures.

- Finance: 5M+P (People, Process, Platform, Partners, Profit) shifts focus to operational and market risks.

These adaptations highlight the framework’s flexibility.

Beyond 6M: 8M and Hybrid Models

In complex systems, some organizations adopt 8M Models, adding Management and Mission to address leadership and strategic alignment. The original 5M framework already included these elements, but their revival underscores the importance of organizational culture in problem-solving. For example, the 4M4(5)E model used in maritime safety analyzes accidents through Man, Machine, Media, Management, Education, Engineering, Enforcement, Example, and Environment.

Integration with RCA Tools

The M frameworks should never be used in isolation. They complement tools like:

- Why-Whys: Drills down into each M category to uncover root causes.

- Fishbone Diagrams: Visualizes interactions between Ms31015.

- FMEA (Failure Mode Effects Analysis): Prioritizes risks within each M.

Contemporary Applications and Challenges

Modern iterations of M frameworks emphasize inclusivity and adaptability. The 5M+P model replaces “Man” with “People” to reflect diverse workforces, while AI-driven factories integrate Machine Learning as a new M. However, challenges persist:

- Overcomplication: Adding too many categories can dilute focus.

- Subjectivity: Teams may prioritize familiar Ms over less obvious factors.

- Dynamic Environments: Rapid technological change necessitates continual framework updates.

Conclusion

The evolution from 4M to 6M and beyond illustrates the iterative nature of quality management. Each expansion reflects deeper insights into how people, processes, and environments interact to create—or resolve—operational challenges. These frameworks will continue to adapt, offering structured yet flexible approaches to root cause analysis. Organizations that master their application will not only solve problems more effectively but also foster cultures of continuous improvement and innovation.

4 thoughts on “How Many M’s Again”