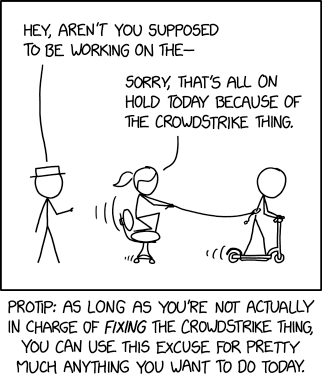

- This is not an unexpected accident. It has happened before on a smaller scale. We’ve seen companies like Crowdstrike under-resource their system controls that should prevent this. There is probably a strong case for regulation here. Maybe the EU will do something.

- Pharma companies should consider situations like the Crowdstrike incident in their business continuity plans. Plan for a week or more of what happened Friday.

- While my flight was only delayed an hour, there were sure to be a lot of grumpy and angry-looking people at Sea-Tac and Logan. I really think if we didn’t have a dysfunctional Congress, we would have seen a real change in how the airline industry is regulated by now.

Category: Uncategorized

Well this was a dizzy ride – thanks SCOTUS for everything (not)

The 2024 U.S. Supreme Court decisions have had significant impacts on the Food and Drug Administration (FDA) and other federal agencies. I don’t think we will truly understand the impact for years as matters move through the courts. This increased uncertainty has led to new questions arising as we assess risk.

Overturning the Chevron Doctrine

A significant decision was made to overturn the Chevron doctrine, a longstanding precedent that mandated courts to defer to federal agencies’ expertise when interpreting unclear statutes. This doctrine has played a crucial role in enabling agencies such as the FDA to establish and enforce regulations based on their specialized knowledge.

- Reduced Authority: With the Chevron doctrine overturned, the FDA’s ability to interpret and enforce regulations without judicial interference is significantly curtailed. This change makes it easier for regulations to be challenged in court, potentially leading to increased litigation and uncertainty in regulatory enforcement.

Challenges to Regulatory Actions

The decisions made by the Supreme Court have made it harder for federal agencies to effectively carry out their regulatory functions. The court’s rulings have extended the time frames for challenging agency actions, leading to delays in implementing new regulations and enforcement actions. This could particularly affect the FDA’s ability to respond promptly to emerging public health issues.

Specific Cases Affecting the FDA

Several other cases have also directly impacted the scope of FDA regulations:

- Environmental and Safety Regulations: Recent court decisions have impacted the FDA’s ability to enforce regulations concerning food safety and environmental protection. For example, the decision to block certain EPA regulations on cross-state pollution indirectly affects the FDA’s responsibility to ensure the safety of food and drugs that might be affected by environmental factors. It’s still uncertain how significant this impact will be, but I am more concerned about this issue than I am about the weakening of the Chevron defense.

- The Supreme Court’s decision to protect access to the abortion medication mifepristone is an important exception. The court upheld the FDA’s regulatory decision, which ensures that the FDA can continue to regulate and approve medications important to public health. However, it’s worth noting that this ruling was specifically about the legal standing of the case, so it’s not an entirely straightforward situation.

Broader Implications

The recent decisions signal a change in the balance of power between the judiciary and federal agencies. The Supreme Court’s decision to limit the deference typically given to agencies such as the FDA has altered the federal regulatory landscape. This change could result in a more restricted and litigious regulatory environment.

Laboratory diagnostic testing regulations

The recent Supreme Court rulings, especially the overturning of the Chevron doctrine in Loper Bright Enterprises v. Raimondo, will first impact the FDA’s new laboratory diagnostic testing regulations.

- Increased Legal Challenges: The removal of Chevron deference means that courts will no longer automatically defer to the FDA’s interpretation of ambiguous statutes. This change might result in more legal disputes regarding the FDA’s power to regulate laboratory-developed tests (LDTs) as medical devices. The American Clinical Laboratory Association (ACLA) has already filed a lawsuit against the FDA over the new LDT rule, and this Supreme Court decision could strengthen their case.

- Uncertainty in Regulatory Framework: The FDA’s final rule, published on May 6, 2024, regulates Laboratory Developed Tests (LDTs) as medical devices, similar to in vitro diagnostics. However, due to a new Supreme Court ruling, the FDA’s authority to regulate LDTs may face greater scrutiny by the courts. This could lead to uncertainty in the regulatory framework for clinical laboratories.

- Potential Delays in Implementation: The Supreme Court’s decision in Corner Post v. Board of Governors extends the timeframe for challenging agency rules. This could lead to delays in the implementation of the FDA’s LDT regulations because stakeholders may now have more time to challenge the rules in court.

- Stricter Scrutiny of FDA Decisions: The new ruling emphasizes that courts should exercise independent judgment in deciding whether an agency has acted within its statutory authority. This could lead to stricter scrutiny of FDA decisions regarding LDT approvals and regulations.

Keep in mind that although these potential impacts are meaningful, the complete effects of the Supreme Court’s rulings on FDA regulations will likely become more apparent over time as cases are presented in court and as the agency adjusts its approach. The situation is still evolving, and those of us involved in FDA regulated industries should be prepared for significant changes ahead.

Shortage Prevention and Mitigation Plans a Reality for Compliance

On June 18, 2024, the EMA issued templates for Shortage Prevention Plans (SPPs) and Mitigation Plans (SMPs). Marketing authorization holders (MAHs) in the European Union/European Economic Area are encouraged to create SPPs to minimize the risk of medicinal shortages. SPPs are already obligatory under Regulation 2022/123 for drugs listed in the list of critical medicines for that particular crisis, and the US has similar guidance.

Shortage Prevention Plans help to identify and manage potential risks in the supply chain and include information on the MAH, the supply and manufacturing chain, key data on stock, sales, consumption, and manufacturing, and an analysis of the history of supply issues. A SPP should be in place for each medicinal product marketed by the MAH. The minimum requirements for the SPP state that MAHs should analyze and evaluate weaknesses in the supply chain. The robustness of shortage prevention measures is to be evaluated. MAHs are obliged to assess the risks of supply interruptions for patients. A medicine shortage risk register should be developed to identify clinically significant products based on therapeutic use and availability of substitutes. Using available information, such as root cause analysis of shortages, the MAH must determine whether corrective and preventive actions or revalidation are needed nationally and internationally. Furthermore, MAHs should maintain minimum stock levels at national levels. Measures to prevent drug shortages should be reviewed regularly.

Shortage Mitigation Plans are designed to eliminate potential or actual drug shortages and minimize the impact on patients. The minimum requirements for the SMPs include procedures for dealing with shortages, from identification to resolution. These procedures should include measures to reduce the shortage’s impact, notification to regulatory authorities, and follow-up actions. MAHs should define roles, responsibilities, and escalation processes and maintain records of root causes and mitigation measures after resolving shortages.

Both should be readily available for submission upon request and can be subject to inspection during GMP and/or GDP inspections or inspections of MAHs. Thus, they should be living documents in the quality system together with the SMF, contamination control strategies, APQRs, and other similar apex documents.

Preventive Maintenance and Calibration

I find that folks often confuse preventive maintenance and calibration. While both processes contribute to overall asset reliability and performance, preventive maintenance focuses on maintaining general functionality, while calibration ensures measurement accuracy. In many cases, calibration can be considered a specialized form of preventive maintenance for measuring instruments. Some equipment may require preventive maintenance and calibration to ensure optimal performance and accuracy. Understanding the difference can be vital to the asset lifecycle. Misunderstanding can lead to poor asset control (and maybe an audit finding or two).

Preventive Maintenance

Preventive maintenance (PM) is a proactive approach to equipment and asset management involving regularly scheduled inspections, cleaning, lubrication, adjustments, repairs, and replacement parts. The goal is to prevent unexpected breakdowns and extend the lifespan of assets.

Purpose

- Prevent equipment failures before they occur

- Extend asset lifespan

- Reduce unplanned downtime

- Improve overall equipment reliability and efficiency

Types

- Time-Based Maintenance (TBM): This involves performing maintenance tasks at fixed time intervals, regardless of the asset’s condition. For example, servicing equipment every 3 months or annually.

- Usage-Based Maintenance: Maintenance is scheduled based on an asset’s actual utilization or operational hours.

- Condition-Based Maintenance (CBM): This approach involves monitoring the actual condition of assets to determine when maintenance should be performed.

- Predictive Maintenance (PdM): This uses data analysis tools and techniques to predict when an asset will likely fail and should be maintained.

- Failure-finding maintenance (FFM) detects hidden failures, typically in protective devices and backup systems.

- Risk-Based Maintenance (RBM): Maintenance activities are prioritized based on the risk assessment of equipment downtime and its impact.

- Prescriptive Maintenance: This predicts when failure will occur, analyzes why, and determines different options to mitigate risks.

- Meter-Based Maintenance: Similar to usage-based maintenance, this type schedules tasks based on equipment meter readings.

These different types of preventive maintenance can be used individually or in combination, depending on the organization’s specific needs, the criticality of the assets, and the available resources. The goal is to prevent unexpected breakdowns, extend equipment life, and optimize maintenance costs

Key components

- Regular inspections

- Cleaning and lubrication

- Adjustments and calibrations

- Minor repairs and parts replacements

Benefits

- Reduced unexpected breakdowns and associated costs

- Improved equipment reliability and performance

- Extended asset lifespan

- Enhanced safety for operators and employees

- Better compliance with warranties and regulations

- Increased productivity due to reduced downtime

Implementation

- Identify critical assets requiring PM

- Develop maintenance schedules based on manufacturer recommendations and historical data.

- Use preventive maintenance software or CMMS (Computerized Maintenance Management System) to manage schedules and work orders.

- Train maintenance staff on PM procedures

- Regularly review and optimize the PM program.

Calibration

Calibration is the act or process of comparing an instrument’s measurements to be calibrated against a traceable reference standard of known accuracy. It involves establishing a relationship between the measurement values of the device under test and those of the calibration standard.

Purpose

- To ensure the accuracy and precision of measuring instruments

- To determine and minimize measurement errors

- To maintain the reliability of measurement results

Process:

- Comparing the device under test with a calibration standard

- Documenting the comparison results

- Adjusting the device if necessary (although, strictly speaking, adjustment is not part of the formal definition of calibration)

Key components

- Traceability: Calibration standards should be traceable through an unbroken chain of comparisons to national or international standards, each with stated uncertainties.

- Uncertainty: Calibration includes the concept of measurement uncertainty, which defines the range of probable values of the measurand and indicates the “goodness” of the calibration process.

- Applications: Calibration is used in various fields, including metrology, engineering, science, and industry. It applies to a wide range of measuring instruments, from simple thermometers to complex electronic devices.

- Frequency: Instruments may require calibration for various reasons, including:

- When new or after repairs

- After a specified time period or usage

- Before critical measurements

- After exposure to conditions that might affect accuracy

Documentation: Calibration procedures are typically documented in specific test methods, capturing all the steps needed to perform a successful calibration.

| Aspect | Preventive Maintenance | Calibration |

|---|---|---|

| Purpose | Prevent equipment failures and extend asset lifespan | Ensure accuracy and precision of measuring instruments |

| Scope | Wide range of activities to keep equipment in good working condition | Focused on measurement accuracy of instruments and devices |

| Frequency | Regular schedule based on time intervals or usage | Specific intervals, after repairs, or when accuracy is critical |

| Outcome | Improved reliability, reduced downtime, extended asset life | Accurate and reliable measurements within acceptable tolerances |

| Process | Cleaning, lubrication, parts replacement, visual inspections | Comparing readings to known standards, making adjustments |

| Applicability | Wide range of equipment and machinery | Specific to measuring instruments and devices |

Cleaning Solution and a Disinfectant Solution

To the average person on the floor, there are just things to clean with. However, cleaning and sanitization are very different, and it’s important to recognize this and ensure folks are properly educated. I can’t count how many audits I’ve had where this became a tripping point.

The primary difference between a cleaning solution and a disinfectant solution lies in their purposes and the outcomes they achieve.

Cleaning Solutions

Purpose: Cleaning solutions are designed to remove dirt, dust, grime, and impurities from surfaces. This process involves using soap, detergents, or other cleaning agents combined with water and physical action (e.g., scrubbing) to lift and wash away contaminants.

Effectiveness: Cleaning physically removes germs from surfaces but does not necessarily kill them. It reduces the number of germs and prepares the surface for further treatment, such as sanitizing or disinfecting.

Examples: Common cleaning agents include all-purpose cleaners, dish soap, and glass cleaners.

Disinfectant Solutions

Purpose: Disinfectant solutions are specifically formulated to kill or inactivate harmful microorganisms on surfaces, including bacteria and viruses. They contain chemical agents that are effective against a wide range of pathogens.

Effectiveness: When used correctly, disinfectants are designed to kill nearly 100% of the germs listed on their labels. They are regulated by the Environmental Protection Agency (EPA) and must meet stringent efficacy standards.

Examples: Common disinfectants include bleach solutions, alcohol-based solutions, and products containing quaternary ammonium compounds (QUATS).

Here is a table comparing the key differences between cleaning solutions and disinfectant solutions:

| Aspect | Cleaning Solutions | Disinfectant Solutions |

|---|---|---|

| Purpose | Remove dirt, dust, grime, and impurities | Kill or inactivate harmful microorganisms |

| Effectiveness | Physically removes germs but does not necessarily kill them | Kills nearly 100% of germs listed on their labels when used correctly |

| Examples | All-purpose cleaners, dish soap, glass cleaners | Bleach solutions, alcohol-based solutions, QUATS |

| Function | Reduces the number of germs | Kills or inactivates germs |

| Usage | First step in the cleaning process | Applied after cleaning to kill remaining germs |

| Regulation | Not always regulated by the EPA unless they have sanitizing or disinfecting claims | Must be registered with the EPA and meet specific efficacy standards |

| Contact Time | Not applicable | Requires specific contact time (usually 5-10 minutes) |

| Safety | Generally safer, fewer precautions needed | May require precautions such as gloves or ventilation |

| Impact on Equipment | Less likely to cause wear and tear on equipment | Can be harsh on surfaces and equipment, potentially causing damage over time |