I have realized I need to build a Part 11 and Annex 11 course. I’ve evaluated some external offerings and decided they really lack that applicability layer, which I am going to focus on.

Here are my draft learning objectives.

21 CFR Part 11 Learning Objectives

- Understanding Regulatory Focus: Understand the current regulatory focus on data integrity and relevant regulatory observations.

- FDA Requirements: Learn the detailed requirements within Part 11 for electronic records, electronic signatures, and open systems.

- Implementation: Understand how to implement the principles of 21 CFR Part 11 in both computer hardware and software systems used in manufacturing, QA, regulatory, and process control.

- Compliance: Learn to meet the 21 CFR Part 11 requirements, including the USFDA interpretation in the Scope and Application Guidance.

- Risk Management: Apply the current industry risk-based good practice approach to compliant electronic records and signatures.

- Practical Examples: Review practical examples covering the implementation of FDA requirements.

- Data Integrity: Understand the need for data integrity throughout the system and data life cycles and how to maintain it.

- Cloud Computing and Mobile Applications: Learn approaches to cloud computing and mobile applications in the GxP environment.

EMA Annex 11 Learning Objectives

- General Guidance: Understand the general guidance on managing risks, personnel responsibilities, and working with third-party suppliers and service providers.

- Validation: Learn best practices for validation and what should be included in validation documentation.

- Operational Phase: During the operational phase, gain knowledge on data management, security, and risk minimization for computerized systems.

- Electronic Signatures: Understand the requirements for electronic signatures and how they should be permanently linked to the respective record, including time and date.

- Audit Trails: Learn about the implementation and review of audit trails to ensure data integrity.

- Security Access: Understand the requirements for security access to protect electronic records and electronic signatures.

- Data Governance: Evaluate the requirements for a robust data governance system.

- Compliance with EU Regulations: Learn how to align with Annex 11 to ensure compliance with related EU regulations.

Course Outline: 21 CFR Part 11 and EMA Annex 11 for IT Professionals

Module 1: Introduction and Regulatory Overview

- History and background of 21 CFR Part 11 and EMA Annex 11

- Purpose and scope of the regulations

- Applicability to electronic records and electronic signatures

- Regulatory bodies and enforcement

Module 2: 21 CFR Part 11 Requirements

- Subpart A: General Provisions

- Definitions of key terms

- Implementation and scope

- Subpart B: Electronic Records

- Controls for closed and open systems

- Audit trails

- Operational and device checks

- Authority checks

- Record retention and availability

- Subpart C: Electronic Signatures

- General requirements

- Electronic signature components and controls

- Identification codes and passwords

Module 3: EMA Annex 11 Requirements

- General requirements

- Risk management

- Personnel roles and responsibilities

- Suppliers and service providers

- Project phase

- User requirements and specifications

- System design and development

- System validation

- Testing and release management

- Operational phase

- Data governance and integrity

- Audit trails and change control

- Periodic evaluations

- Security measures

- Electronic signatures

- Business continuity planning

Module 4: PIC/S Data Integrity Requirements

- Data Governance System

- Structure and control of the Quality Management System (QMS)

- Policies related to organizational values, quality, staff conduct, and ethics

- Organizational Influences

- Roles and responsibilities for data integrity

- Training and awareness programs

- General Data Integrity Principles

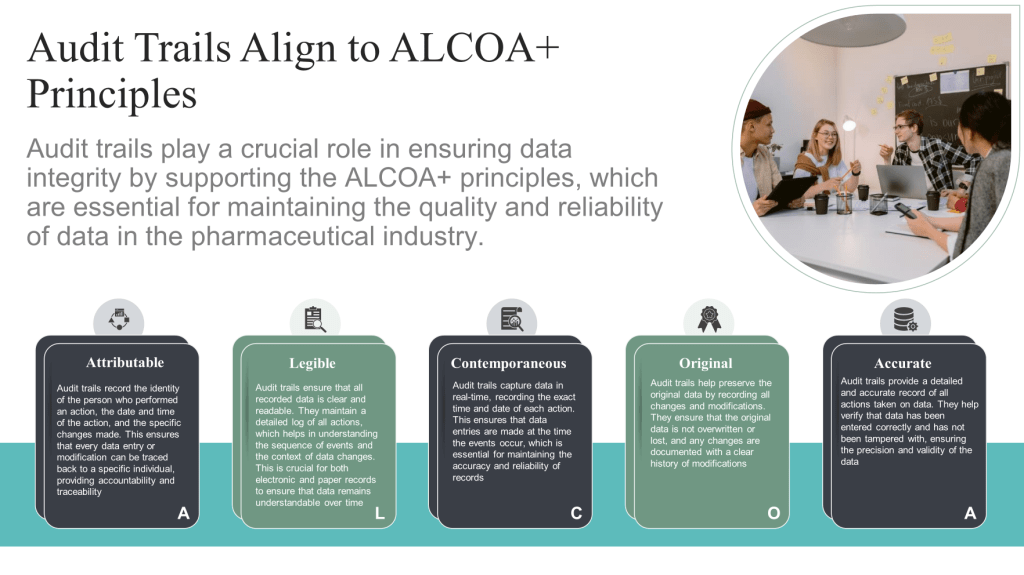

- ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, Accurate, Complete, Consistent, Enduring, and Available)

- Data lifecycle management

- Specific Considerations for Computerized Systems

- Qualification and validation of computerized systems

- System security and access controls

- Audit trails and data review

- Management of hybrid systems

- Outsourced Activities

- Data integrity considerations for third-party suppliers

- Contractual agreements and oversight

- Regulatory Actions and Remediation

- Responding to data integrity issues

- Remediation strategies and corrective actions

- Periodic System Evaluation

- Regular reviews and re-validation

- Risk-based approach to system updates and maintenance

Module 5: Compliance Strategies and Best Practices

- Interpreting regulatory guidance documents

- Conducting risk assessments

- Our validation approach

- Leveraging suppliers and third-party service providers

- Implementing audit trails and electronic signatures

- Data integrity and security controls

- Change and configuration management

- Training and documentation requirements

Module 6: Case Studies and Industry Examples

- Review of FDA warning letters and 483 observations

- Lessons learned from industry compliance initiatives

- Practical examples of system validation and audits

Module 7: Future Trends and Developments

- Regulatory updates and revisions

- Impact of new technologies (AI, cloud, etc.)

- Harmonization efforts between global regulations

- Continuous compliance monitoring

The course will include interactive elements such as hands-on exercises, quizzes, and group discussions to reinforce the learning objectives. The course will provide practical insights for IT professionals by focusing on real-world examples from our company.