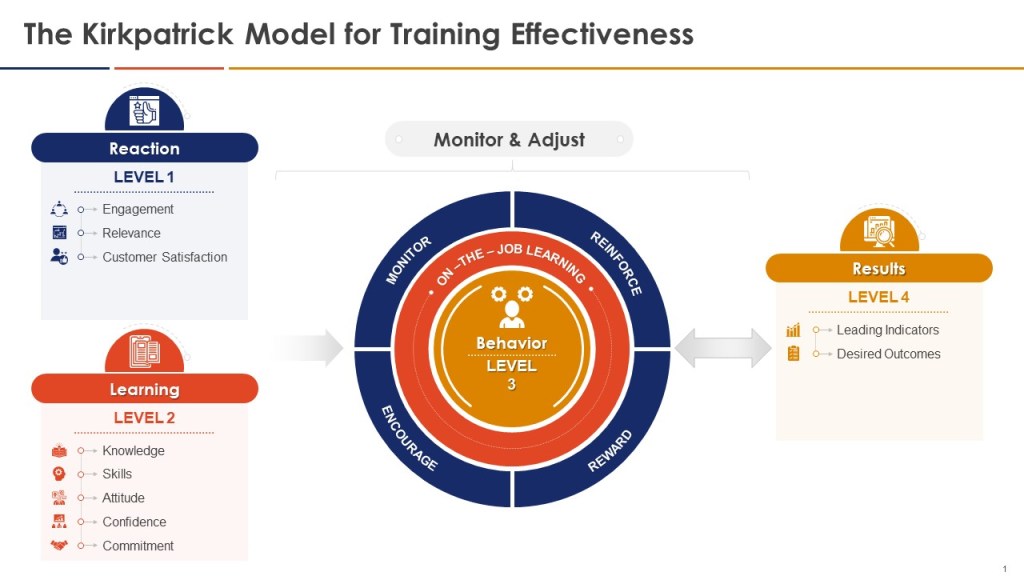

In the Kilpatrick model, a level 2 assessment measures how much individuals learned. It is asking did the learners actually learn what we wanted them to learn? Did we actually advance knowledge?

For many of us, the old go-to is the multiple-choice quiz.

If we actually want to assess a learner’s ability to do something or think critically about a topic, a multiple-choice quiz isn’t going to work. This isn’t to say that a multiple-choice quiz can’t be challenging, but the focus of a multiple-choice quiz is on the learner’s understanding of the content, not on the learner’s knowledge of how to apply the content to a variety of different contexts.

Say we are designing a root cause analysis course. By the end of the course, your learners should be able to understand some core principles of root cause analysis so that they can perform better investigations, find root causes and determine appropriate CAPAs. While there may be some inherently wrong approaches to root cause analysis that could be assessed in a multiple-choice quiz, a skilled investigator will likely not be dealing with obvious “right” and “wrong” ways to identify causes. Most investigations require complex interactions with people. As such, there may be multiple decisions an investigator needs to make and, within the scope of a course, it could be really hard to identify what skills a budding investigator needs to develop through multiple-choice quizzes alone.

So, what kinds of assessments could you use beyond multiple-choice quizzes and when should you use them? There’s a lot of complexity to these choices which ultimately need to align what

you want people in the course to learn with how you think they can best demonstrate evidence of that learning.

| Assessment Instrument | When to use it | Example |

| Multiple-Choice Quiz or Exam | To assess a learner’s understanding of a concept, definition, or specific process. Could also be used to assess responses or reactions to a scenario-based question if there are clear “right” or “wrong” responses. | Understanding of core concepts of root cause analysis. Simple branching choices, for example what tool to use when. |

| Open-Ended Questions | To assess a learner’s ability to interpret and apply a new idea. Could also be used to assess a learner’s ability to describe an approach to a process or problem. | Demonstrate knowledge of root cause analysis techniques through various practice exercises. |

| Long-Form Written Assignment | To assess a learner’s ability to make an argument, analyze a text or current event, or use outside evidence to inform a particular claim. Could also be used to assess a learner’s understanding of how to produce a piece of writing specific to a particular field or discipline (for example, a lab report in a lab sciences context or a policy memo in a public policy context). | Write an analysis and investigation report up from a example. |

| Project | To assess a learner’s ability to make a new product and apply skills learned to build an independent work. Could also be used to assess a learner’s understanding of how to create a field-specific artifact. | Conduct a root cause analysis from an exercise. On the job training. |

| Portfolio | To assess a learner’s ability to grow, revise, and create a body of work over a particular period of time. | Review of investigations on periodic basis |

A lot of learning experiences will implement a combination of these types of assessments in a course, and it’s likely that at different phases of your course and for different purposes, you

will need to select more than one assessment or evaluation method.

Remember that an assessment serves two additional purposes: It helps the learners recognize where they are in the course so that they have an understanding of the progress, and it helps you, as the facilitator, see what challenges and triumphs the learners are experiencing all the way throughout the course.