A curated exploration of the minds that have shaped my approach to organizational excellence, systems thinking, and quality culture

Quality management has evolved far beyond its industrial roots to become a sophisticated discipline that draws from psychology, systems theory, organizational behavior, and strategic management. The intellectual influences that shape how we think about quality today represent a rich tapestry of thinkers who have fundamentally changed how organizations approach excellence, learning, and continuous improvement.

This guide explores the key intellectual influences that inform my quality thinking, organized around the foundational concepts they’ve contributed. For each thinker, I’ve selected two essential books that capture their most important contributions to quality practice.

I want to caution that this list is not meant to be complete. It really explores some of the books I’ve been using again and again as I explore many of the concepts on this blog. Please share your foundational books in the comments!

And to make life easier, I provided links to the books.

https://bookshop.org/lists/quality-thinkers

Psychological Safety and Organizational Learning

Amy Edmondson

The pioneer of psychological safety research

Amy Edmondson’s work has revolutionized our understanding of how teams learn, innovate, and perform at their highest levels. Her research demonstrates that psychological safety—the belief that one can speak up without risk of punishment or humiliation—is the foundation of high-performing organizations.

Essential Books:

- The Fearless Organization: Creating Psychological Safety in the Workplace for Learning, Innovation, and Growth (2018) – The definitive guide to understanding and building psychological safety in organizations.

- The 4 Stages of Psychological Safety (HBR Emotional Intelligence Series) (2024) – A practical handbook featuring Edmondson’s latest insights alongside other leading voices in the field.

Timothy Clark

The architect of staged psychological safety development

Timothy Clark has extended Edmondson’s foundational work by creating a practical framework for how psychological safety develops in teams. His four-stage model provides leaders with a clear pathway for building psychologically safe environments.

Essential Books:

- The 4 Stages of Psychological Safety: Defining the Path to Inclusion and Innovation (2020) – Clark’s comprehensive framework for understanding how teams progress through inclusion safety, learner safety, contributor safety, and challenger safety.

- The 4 Stages of Psychological Safety™ Behavioral Guide (2025) – A practical companion with over 120 specific behaviors for implementing psychological safety in daily work.

Decision-Making and Risk Management

Gerd Gigerenzer

The champion of bounded rationality and intuitive decision-making

Gigerenzer’s work challenges the notion that rational decision-making requires complex analysis. His research demonstrates that simple heuristics often outperform sophisticated analytical models, particularly in uncertain environments—a key insight for quality professionals facing complex organizational challenges.

Essential Books:

- Risk Savvy: How to Make Good Decisions (2014) – A practical guide to understanding risk and making better decisions in uncertain environments.

- Gut Feelings: The Intelligence of the Unconscious (2007) – Explores how intuitive decision-making can be superior to analytical approaches in many situations.

Change Management and Organizational Transformation

John Kotter

The authority on leading organizational change

Kotter’s systematic approach to change management has become the standard framework for organizational transformation. His eight-step process provides quality leaders with a structured approach to implementing quality initiatives and cultural transformation.

Essential Books:

- Leading Change (2012) – The classic text on organizational change management featuring Kotter’s legendary eight-step process.

- Our Iceberg Is Melting: Changing and Succeeding Under Any Conditions (2006) – A business fable that makes change management principles accessible and memorable.

Systems Thinking and Organizational Design

Donella Meadows

The systems thinking pioneer

Meadows’ work on systems thinking provides the intellectual foundation for understanding organizations as complex, interconnected systems. Her insights into leverage points and system dynamics are essential for quality professionals seeking to create sustainable organizational change.

Essential Books:

- Thinking in Systems (2008) – The essential introduction to systems thinking, with practical examples and clear explanations of complex concepts.

Peter Senge

The learning organization architect

Senge’s concept of the learning organization has fundamentally shaped how we think about organizational development and continuous improvement. His five disciplines provide a framework for building organizations capable of adaptation and growth.

Essential Books:

- The Fifth Discipline: The Art & Practice of the Learning Organization (2006) – The foundational text on learning organizations and the five disciplines of systems thinking.

- The Fifth Discipline Fieldbook: Strategies and Tools for Building a Learning Organization (1994) – A practical companion with tools and techniques for implementing learning organization principles.

Edgar Schein

The organizational culture architect

Schein’s three-layer model of organizational culture (artifacts, espoused values, and basic assumptions) is fundamental to your approach to quality culture assessment and development. Schein’s work provides the structural foundation for understanding how culture actually operates in organizations.

Essential Books:

- Organizational Culture and Leadership (5th Edition, 2016) – The definitive text on understanding and changing organizational culture, featuring the three-level model that shapes your quality culture work.

- Humble Inquiry: The Gentle Art of Asking Instead of Telling (2013) – Essential insights into leadership communication and building psychological safety through questioning rather than commanding.

Quality Management and Continuous Improvement

W. Edwards Deming

The quality revolution catalyst

Deming’s work forms the philosophical foundation of modern quality management. His System of Profound Knowledge provides a comprehensive framework for understanding how to transform organizations through quality principles.

Essential Books:

- Out of the Crisis (1982) – Deming’s classic work introducing the 14 Points for Management and the foundations of quality transformation.

- The New Economics for Industry, Government, Education (2000) – Deming’s mature thinking on the System of Profound Knowledge and its application across sectors.

Worker Empowerment and Democratic Management

Mary Parker Follett

The prophet of participatory management

Follett’s early 20th-century work on “power-with” rather than “power-over” anticipated modern approaches to worker empowerment and participatory management. Her insights remain remarkably relevant for building quality cultures based on worker engagement.

Essential Books:

- Mary Parker Follett: Prophet of Management (1994) – A collection of Follett’s essential writings with commentary by leading management thinkers.

- The New State: Group Organization the Solution of Popular Government (1918) – Follett’s foundational work on democratic organization and group dynamics.

Data Communication, Storytelling and Visual Thinking

Nancy Duarte

The data storytelling pioneer

Duarte’s work bridges the gap between data analysis and compelling communication. Her frameworks help quality professionals transform complex data into persuasive narratives that drive action.

Essential Books:

- DataStory: Explain Data and Inspire Action Through Story (2019) – The definitive guide to transforming data into compelling narratives that inspire action.

- Slide:ology: The Art and Science of Creating Great Presentations (2008) – Essential techniques for visual communication and presentation design.

Dave Gray

The visual thinking and organizational innovation pioneer

Gray’s work bridges abstract organizational concepts and actionable solutions through visual frameworks, collaborative innovation, and belief transformation. His methodologies help quality professionals make complex problems visible, engage teams in creative problem-solving, and transform the beliefs that undermine quality culture.

Essential Books:

- Gamestorming: A Playbook for Innovators, Rulebreakers, and Changemakers (2010) – Co-authored with Sunni Brown and James Macanufo, this foundational text provides over 80 structured activities for transforming how teams collaborate, innovate, and solve problems. Essential for quality professionals seeking to make quality improvement more engaging and creative. Now in a 2nd edition!

- Liminal Thinking: Create the Change You Want by Changing the Way You Think (2016) – Gray’s most profound work on organizational transformation, offering nine practical approaches for transforming the beliefs that shape organizational reality.

Strategic Planning and Policy Deployment

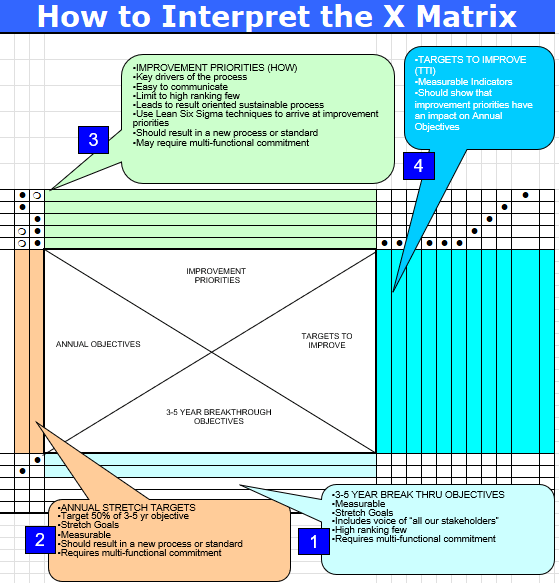

Hoshin Kanri Methodology

The Japanese approach to strategic alignment

While not attributed to a single author, Hoshin Kanri represents a sophisticated approach to strategic planning that ensures organizational alignment from top to bottom. The X-Matrix and catch-ball processes provide powerful tools for quality planning.

Essential Books:

- Implementing Hoshin Kanri: How to Manage Strategy Through Policy Deployment and Continuous Improvement (2021) – A comprehensive guide to implementing Hoshin Kanri based on real-world experience with 14 companies.

- Hoshin Kanri: Policy Deployment for Successful TQM (1991) – The classic introduction to Hoshin planning principles and practice.

Lean Manufacturing and Process Excellence

Taiichi Ohno and Shigeo Shingo

The Toyota Production System architects

These two pioneers created the Toyota Production System, which became the foundation for lean manufacturing and continuous improvement methodologies worldwide.

Essential Books:

- Toyota Production System: Beyond Large-Scale Production by Taiichi Ohno (1988) – The creator of TPS explains the system’s foundations and philosophy.

- Fundamental Principles of Lean Manufacturing by Shigeo Shingo (2021) – Recently translated classic providing deep insights into process improvement thinking.

Strategic Decision-Making and Agility

John Boyd

The OODA Loop creator

Boyd’s work on rapid decision-making cycles has profound implications for organizational agility and continuous improvement. The OODA Loop provides a framework for staying ahead of change and competition.

Essential Books:

- Science, Strategy and War: The Strategic Theory of John Boyd by Frans Osinga (2007) – The most comprehensive analysis of Boyd’s strategic thinking and its applications.

- Certain to Win: The Strategy of John Boyd, Applied to Business by Chet Richards (2004) – Practical application of Boyd’s concepts to business strategy.

Dave Snowden

The complexity theory pioneer and creator of the Cynefin framework

Snowden’s work revolutionizes decision-making by providing practical frameworks for navigating uncertainty and complexity. The Cynefin framework helps quality professionals understand what type of situation they face and choose appropriate responses, distinguishing between simple problems that need best practices and complex challenges requiring experimentation.

Essential Books:

- Cynefin – Weaving Sense-Making into the Fabric of Our World (2020) – The comprehensive guide to the Cynefin framework and its applications across healthcare, strategy, organizational behavior, and crisis management. Essential for quality professionals seeking to match their response to the nature of their challenges.

- A Leader’s Framework for Decision Making (2007 Harvard Business Review) – Co-authored with Mary Boone, this article provides the essential introduction to complexity-based decision-making. Critical reading for understanding when traditional quality approaches work and when they fail.

This guide represents a synthesis of influences that shape my quality thinking. Each recommended book offers unique insights that, when combined, provide a comprehensive foundation for quality leadership in the 21st century.