|

Requirement |

Description |

|

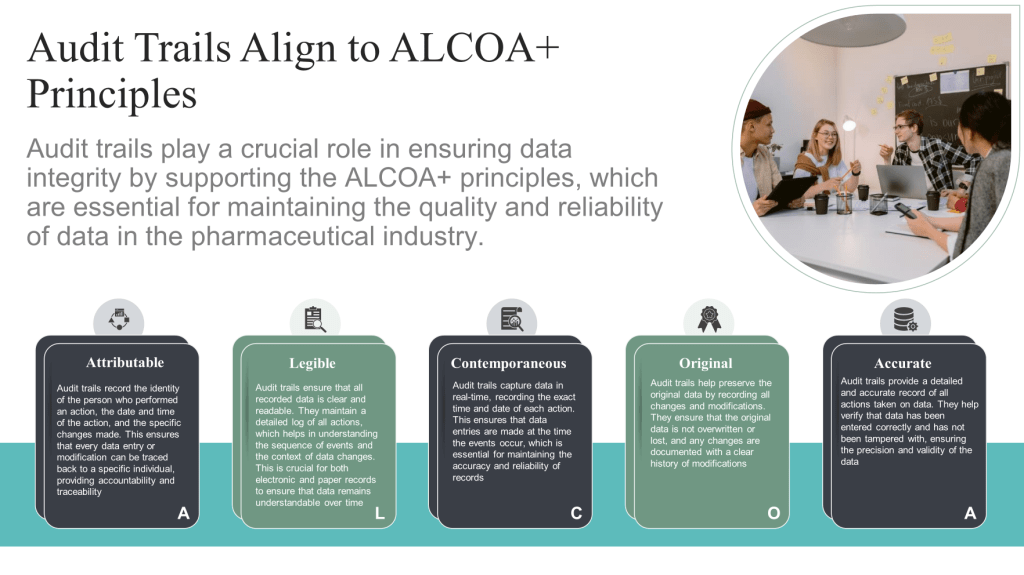

Attributable (Traceable) |

|

|

Legible |

|

|

Contemporaneous |

|

|

Original |

|

|

Accurate |

|

|

Complete |

|

|

Consistent |

|

|

Enduring |

|

|

Available |

|

21CFR Part 11 Requirements

Definition: An audit trail is a secure, computer-generated, time-stamped electronic record that allows for the reconstruction of events related to the creation, modification, and deletion of an electronic record.

Requirements:

- Availability: Audit trails must be easily accessible for review and copying by the FDA during inspections.

- Automation: Entries must be automatically captured by the system without manual intervention.

- Components: Each entry must include a timestamp, user ID, original and new values, and reasons for changes where applicable.

- Security: Audit trail data must be securely stored and not accessible for editing by users

EMA Annex 11 (Eudralex Volume 4) Requirements

Definition: Audit trails are records of all GMP-relevant changes and deletions, created by the system to ensure traceability and accountability.

Requirements:

- Risk-Based Approach: Building audit trails into the system for all GMP-relevant changes and deletions should be considered based on a risk assessment.

- Documentation: The reasons for changes or deletions must be documented.

- Review: Audit trails must be available, convertible into a generally readable form, and regularly reviewed.

- Validation: The audit trail functionality must be validated to ensure it captures all necessary data accurately and securely.

Requirements from PIC/S GMP Data Integrity Guidance

Definition: Audit trails are metadata recorded about critical information such as changes or deletions of GMP/GDP relevant data to enable the reconstruction of activities.

Requirements:

- Review: Critical audit trails related to each operation should be independently reviewed with all other records related to the operation, especially before batch release.

- Documentation: Significant deviations found during the audit trail review must be fully investigated and documented.