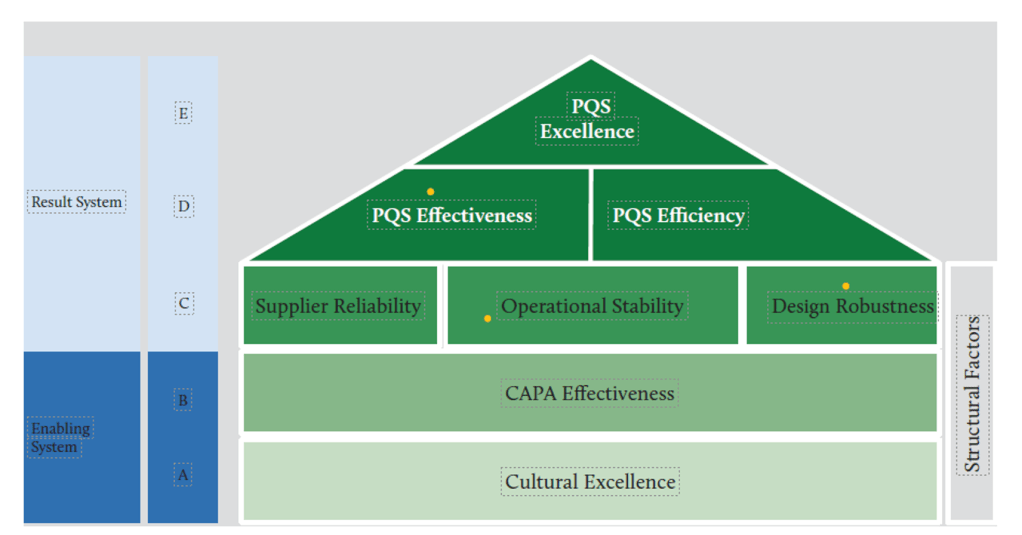

I do love a house metaphor or visualization, almost as I like a good tree, and this visualization of the house of quality is one I often return to. I want to turn to the question of efficiency, as it is often one I hear stressed by many leaders, and frankly I think the use can get a little off-kilter.

We can define efficiency as the “productivity of a process and the utilization of resources.” The St Gallen reports commissioned by the FDA as part of the quality metrics initiative finds that efficiency and effectiveness in pharmaceutical quality systems are positively correlated, though the relationship is not as strong as some may expect.

The study analyzed data from over 60 pharmaceutical manufacturing plants found a slight positive correlation between measures of quality system effectiveness and efficiency. This indicates that plants with more effective quality systems also tend to be more efficient in their operations. However, effectiveness only explained about 4% of the variation in efficiency scores, suggesting other factors play a major role as well.

To dig deeper, the researchers separated plants into four groups based on their levels of quality effectiveness and efficiency. The top performing group excelled in both areas, while the lowest group struggled with both. Interestingly, there were also groups that performed well in one area but not the other. This reveals that effectiveness and efficiency, while related, are distinct capabilities that must be built separately.

What really set apart the top performers was their higher implementation of operational excellence practices across areas like total productive maintenance, quality management, and just-in-time production. They also tended to have more empowered employees and a stronger culture of continuous improvement. This suggests that building these foundational capabilities is key to achieving both quality and efficiency.

The research provides evidence that quality and efficiency can be mutually reinforcing when the right systems and culture are in place. However, it also shows this is not automatic – companies must be intentional about developing both in tandem. Those that focus solely on efficiency without building quality maturity may struggle to sustain performance in the long run. The most successful manufacturers find ways to make quality a driver of operational excellence, not a constraint on it.

Dangers of an Excessive Focus on Efficiency

An excessive focus on efficiency in organizations can further lead to several unintended negative consequences:

Reduced Resilience and Flexibility

Prioritizing efficiency often involves streamlining processes, reducing redundancies, and optimizing resource allocation. While this can boost short-term productivity, it can also make organizations less resilient to unexpected disruptions.

Stifled Innovation and Creativity

Efficiency-driven environments tend to emphasize standardization and predictability, which can hinder innovation. When resources are tightly controlled and risk-aversion is high, there’s little room for experimentation and creative problem-solving. This can leave companies vulnerable to being outpaced by more innovative competitors.

Employee Burnout and Disengagement

Pushing for ever-increasing efficiency can lead to work environments where employees are constantly pressured to do more with less. This approach can increase stress levels, leading to burnout, reduced morale, and ultimately, lower overall productivity. Overworked employees may struggle with work-life balance and experience health issues, potentially resulting in higher turnover rates.

Compromised Quality

There’s often a delicate balance between efficiency and quality. In the pursuit of faster and cheaper ways of doing things, organizations may inadvertently compromise on product or service quality. Over time, this can erode brand reputation and customer loyalty.

Short-term Focus at the Expense of Long-term Success

An overemphasis on efficiency can lead to a myopic focus on short-term gains while neglecting long-term strategic objectives. This can result in missed opportunities for sustainable growth and innovation.

Resource Dilution and Competing Priorities

When organizations try to be efficient across too many initiatives simultaneously, it can lead to resource dilution. This often results in many projects being worked on, but few being completed effectively or on time. Competing priorities can also lead to different departments working at cross-purposes, potentially canceling out each other’s efforts.

Loss of Human Connection and Engagement

Prioritizing task efficiency over human connection can have significant negative impacts on workplace culture and employee engagement. A lack of connection in the workplace can chip away at healthy mindsets and organizational culture.

Reduced Adaptability to Change

Highly efficient systems are often optimized for specific conditions. When those conditions change, such systems may struggle to adapt. This can leave organizations vulnerable in rapidly changing business environments.

To mitigate these risks, organizations should strive for a balance between efficiency and other important factors such as resilience, innovation, and employee well-being. This may involve maintaining some redundancies, allowing for periods of “productive inefficiency,” and fostering a culture that values both productivity and human factors.

Quality and Efficiency

Building efficiency from quality, often referred to as “Good Quality – Good Business”, is best tackled by:

- Reduced waste and rework: By focusing on quality, companies can reduce defects, errors, and the need for rework. This directly improves efficiency by reducing wasted time, materials, and labor.

- Improved processes: Quality initiatives often involve analyzing and optimizing processes. These improvements can lead to more streamlined operations and better resource utilization.

- Enhanced reliability: High-quality products and processes tend to be more reliable. This reliability can reduce downtime, maintenance costs, and other inefficiencies.

- Cultural excellence: Organizations with a higher levels of cultural excellence, including employee engagement and continuous improvement mindsets supports both quality and efficiency improvements.

The important thing to remember is efficiency that does not help the worker, that does not build resilience, is not efficiency at all.

good stuff

LikeLike