As quality professionals and leaders of all stripes information bombards us from all directions. This is why the ability to truly listen is a core and valuable skill. Whether in personal relationships, professional settings, or casual interactions, effective listening can be the key to building stronger connections, resolving conflicts, and fostering mutual understanding.

In this post, I want to look at four powerful techniques that I am working to refine to continually improve my listening skills, and that can help you in your journey to be a more empathetic and insightful communicator.

The Importance of Active Listening

Before we explore the techniques, it’s crucial to understand why active listening is so vital. Active listening goes beyond merely hearing words; it involves fully engaging with the speaker, processing their message, and responding thoughtfully. This skill can lead to:

- Improved relationships and trust

- Better problem-solving and decision-making

- Reduced misunderstandings and conflicts

- Enhanced empathy and emotional intelligence

- Increased productivity in professional settings

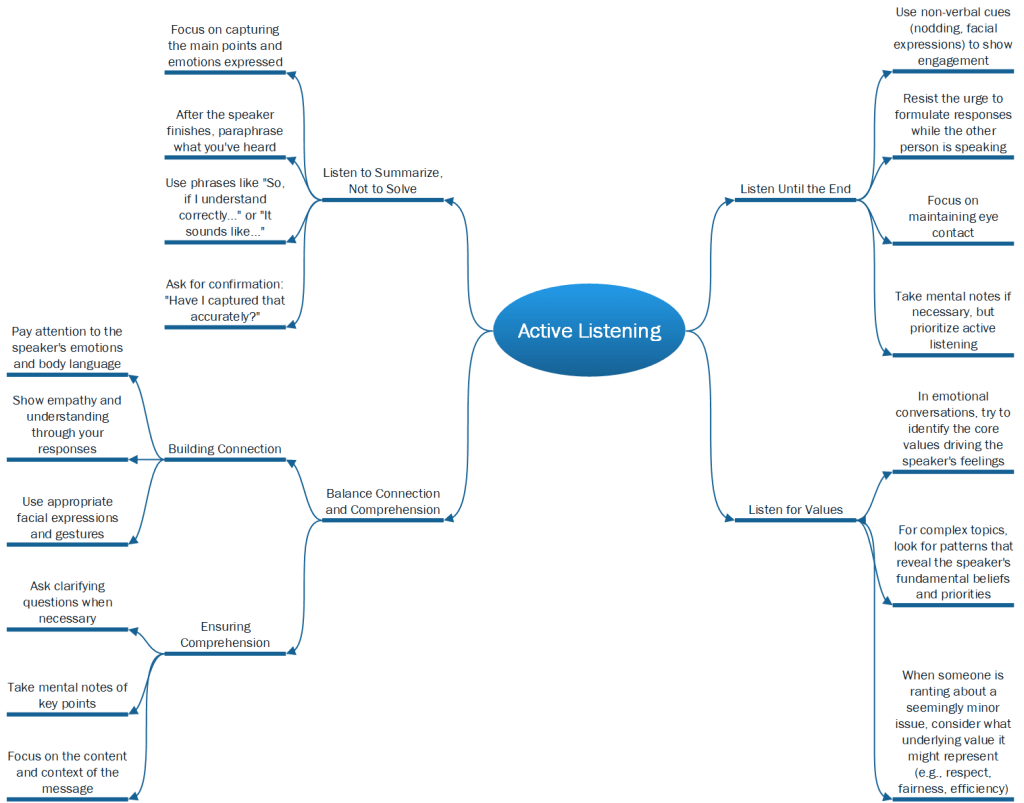

Now, let’s dive into the four techniques that can elevate your listening game.

Technique 1: Listen Until the End

The Power of Patience

One of the most common pitfalls in communication is the tendency to interrupt or jump in before the speaker has finished expressing their thoughts. This habit not only disrupts the flow of conversation but also sends a message that you value your own input more than the speaker’s.

Benefits of Listening Completely:

- You gain a full understanding of the speaker’s perspective

- The speaker feels respected and valued

- You avoid making premature judgments or assumptions

How to Practice:

- Focus on maintaining eye contact

- Use non-verbal cues (nodding, facial expressions) to show engagement

- Resist the urge to formulate responses while the other person is speaking

- Take mental notes if necessary, but prioritize active listening

By allowing the speaker to complete their thoughts without interruption, you create an environment of trust and openness, which is essential for effective communication.

Technique 2: Listen to Summarize, Not to Solve

The Art of Understanding

When someone shares a problem or concern, our natural instinct is often to jump into problem-solving mode. However, this approach can be counterproductive, especially if the speaker is simply looking to be heard and understood.

Why Summarizing is Crucial:

- It ensures you’ve accurately grasped the speaker’s message

- It demonstrates that you’re fully engaged in the conversation

- It allows the speaker to clarify any misunderstandings

- It gives the speaker a chance to reflect on their own thoughts

Implementing This Technique:

- Focus on capturing the main points and emotions expressed

- After the speaker finishes, paraphrase what you’ve heard

- Use phrases like “So, if I understand correctly…” or “It sounds like…”

- Ask for confirmation: “Have I captured that accurately?”

By prioritizing understanding over immediate problem-solving, you create a space where the speaker feels truly heard, which can often lead to more effective resolution of issues in the long run.

Technique 3: Balance Connection and Comprehension

The Dual Focus of Effective Listening

Listening is not just about absorbing information; it’s also about building a connection with the speaker. Striking the right balance between these two aspects is crucial for meaningful communication.

Aspects to Focus On:

- Building Connection:

- Pay attention to the speaker’s emotions and body language

- Show empathy and understanding through your responses

- Use appropriate facial expressions and gestures

- Ensuring Comprehension:

- Focus on the content and context of the message

- Ask clarifying questions when necessary

- Take mental notes of key points

Strategies for Balancing Both:

- Practice active empathy by putting yourself in the speaker’s shoes

- Use reflective listening techniques to confirm understanding while showing support

- Alternate between focusing on emotional cues and factual content

By mastering this balance, you not only gain a deeper understanding of the issue at hand but also strengthen your relationship with the speaker, fostering trust and open communication.

Technique 4: Listen for Values

Uncovering the Hidden Layers

Every conversation, whether it’s a casual chat or an emotional outpouring, offers a window into the speaker’s values and priorities. By tuning into these underlying messages, you can gain profound insights into what truly matters to the person you’re communicating with.

Why Listening for Values Matters:

- It deepens your understanding of the speaker’s motivations

- It helps you respond more empathetically and effectively

- It strengthens your connection by showing genuine interest in the speaker’s worldview

How to Identify Values in Conversation:

- Pay attention to recurring themes or concerns

- Notice what elicits strong emotional responses

- Listen for statements about what “should” or “ought to” be

- Observe which topics the speaker spends the most time on

Applying This Technique:

- When someone is ranting about a seemingly minor issue, consider what underlying value it might represent (e.g., respect, fairness, efficiency)

- In emotional conversations, try to identify the core values driving the speaker’s feelings

- For complex topics, look for patterns that reveal the speaker’s fundamental beliefs and priorities

By listening for values, you transform every interaction into an opportunity for deeper understanding and connection, enriching your relationships and broadening your perspective.

Conclusion

Mastering these four listening techniques – listening until the end, summarizing rather than solving, balancing connection and comprehension, and listening for values – can revolutionize your communication skills. These strategies not only enhance your ability to understand and connect with others but also contribute to your personal and professional growth.

Remember, effective listening is a skill that requires practice and patience. As you implement these techniques in your daily interactions, you’ll likely find that your conversations become more meaningful, your relationships stronger, and your understanding of others more profound. In a world where genuine connection is increasingly valuable, honing your listening skills is an investment that pays dividends in all areas of life.

So, the next time you engage in a conversation, challenge yourself to apply these techniques. You might be surprised at how much you can learn and how much deeper your connections can become when you truly listen with intention and care.