The recent FDA warning letter issued to Sanofi on January 15, 2025 highlights a critical issue that continues to plague pharmaceutical manufacturers – inadequate investigation of deviations. Specifically, the FDA cited Sanofi for “failure to thoroughly investigate any unexplained discrepancy or failure of a batch or any of its components to meet any of its specifications, whether or not the batch has already been distributed.”

This observation underscores the importance of robust deviation investigation and CAPA (Corrective and Preventive Action) systems.

The Importance of Thorough Investigations

Investigating deviations is not just a regulatory requirement – it’s a critical part of ensuring product quality and patient safety. The objective of an investigation is not merely to perform the investigation, but to improve the reliability of our manufacturing operations, the ultimate objective being increased quality and availability of those regulated healthcare products.

When companies fail to thoroughly investigate deviations, they miss opportunities to:

- Identify root causes of quality issues

- Implement effective corrective actions

- Prevent recurrence of similar problems

- Improve overall manufacturing processes and controls

Common Pitfalls in Deviation Investigations

Some common reasons why deviation investigations fall short include:

- Lack of trained, competent investigators

- Inadequate time and resources allocated to investigations

- Pressure to close investigations quickly

- Failure to look beyond the immediate symptoms to identify true root causes

- Over-reliance on “human error” as a root cause

- Poor documentation of investigation activities and rationale

Building Better Investigation and CAPA Processes

To overcome these challenges and build more effective investigation and CAPA systems, companies should consider the following approaches:

1. Develop Investigator Competencies

Having competent investigators is crucial. Companies should:

- Define required competencies for investigators

- Provide comprehensive training on investigation techniques and tools

- Implement mentoring programs for new investigators

- Regularly assess and refresh investigator skills

2. Implement a Risk-Based Approach

Not all deviations require the same level of investigation. Using a risk-based approach allows companies to:

- Prioritize critical deviations for in-depth investigation

- Allocate appropriate resources based on potential impact

- Ensure thorough investigations for high-risk issues

3. Use Structured Investigation Methods

Adopting structured investigation methods helps ensure consistency and thoroughness. Some useful tools include:

- Fishbone diagrams for brainstorming potential causes

- Why-Why analysis for drilling down to root causes

- Fault tree analysis for complex issues

- Timeline analysis to understand the sequence of events

4. Look Beyond Human Error

Human error is not a root cause. Instead of stopping at “operator error”, investigators should dig deeper to understand:

- Why the error occurred

- What system or process factors contributed to the error

- How similar errors can be prevented in the future

5. Improve Documentation Practices

Thorough documentation is essential for demonstrating the adequacy of investigations to regulators. Key elements include:

- Clear description of the deviation

- Investigation steps taken

- Data and evidence collected

- Root cause analysis

- Rationale for conclusions

- Corrective and preventive actions

6. Implement Effective CAPAs

The investigation is only the first step – implementing effective corrective and preventive actions is crucial. Companies should:

- Ensure CAPAs directly address identified root causes

- Consider both short-term corrections and long-term preventive measures

- Assess potential risks of proposed CAPAs

- Establish clear timelines and accountability for CAPA implementation

- Conduct effectiveness checks to verify CAPA impact

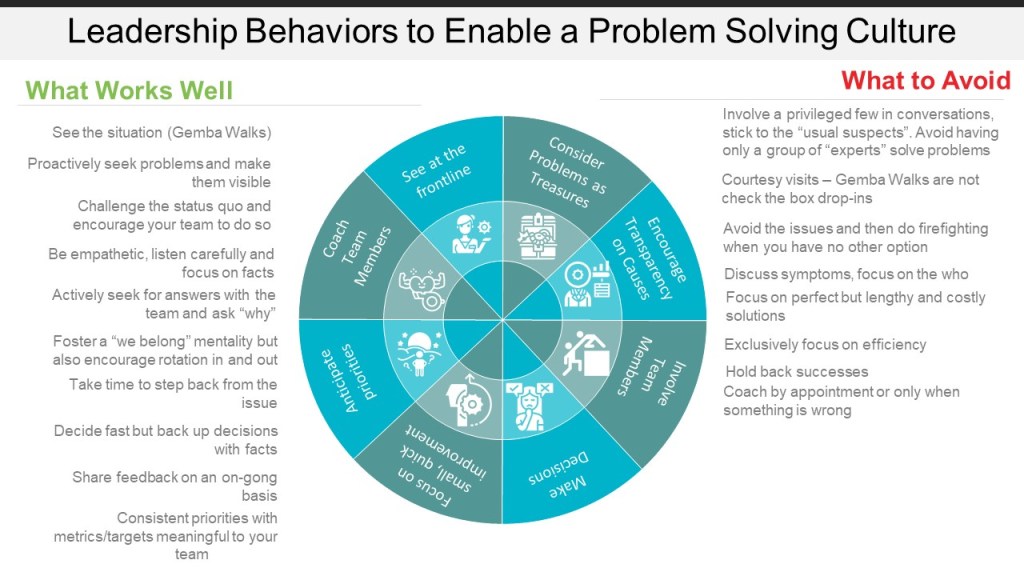

7. Foster a Culture of Quality

Management plays a critical role in creating an environment that supports thorough investigations.

- Providing adequate time and resources for investigations

- Encouraging open reporting of deviations without fear of blame

- Recognizing and rewarding thorough investigation practices

- Leading by example in prioritizing quality and patient safety

Common Pitfalls in Investigating Microbiological Contamination Events

When investigating microbiological contamination events there are often several pitfalls that can hinder the effectiveness of their investigations.

Inadequate Root Cause Analysis

One of the most significant pitfalls is failing to conduct a thorough root cause analysis. Investigators may be tempted to attribute contamination to superficial causes like “human error” without digging deeper into systemic issues. This shallow approach often leads to ineffective corrective actions that fail to prevent recurrence. Build in safeguards to avoid jumping to conclusion.

Overlooking Environmental Factors

Investigators sometimes neglect to consider the broader environmental context of contamination events. Factors such as air handling systems, water quality, and even compressed air can harbor contaminants. Failing to examine these potential sources may result in missed opportunities for identifying the true origin of contamination.

Insufficient Microbial Identification

Relying solely on phenotypic identification methods can lead to misidentification of contaminants. Phenotypic results can incorrectly point to laboratory contamination, while genotypic testing revealed a production-related issue. Using a combination of identification methods, including genotypic techniques, can provide more accurate and actionable results.

Premature Conclusion of Investigations

Pressure to close investigations quickly can lead to premature conclusions. This was evident in the Sanofi warning letter, where the FDA noted that investigations into critical deviations, including multiple microbiological contamination events, were inadequate. Rushing the process can result in overlooking important details and failing to implement effective corrective actions.

Failure to Consider Cross-Contamination

Investigators may not always consider the possibility of cross-contamination between products or areas within the facility. The presence of drug-resistant microbial contaminants, as observed in some studies, underscores the importance of examining potential routes of transmission and implementing strict hygiene procedures.

Inadequate Documentation

Poor documentation of investigation activities and rationale can undermine the credibility of findings and make it difficult to justify conclusions to regulators. The FDA’s warning letter to Sanofi highlighted this issue, noting that not all investigational activities were documented.

Neglecting Trending and Data Analysis

Failing to analyze contamination events in the context of historical data and trends can lead to missed patterns and recurring issues. Establishing and maintaining a comprehensive microflora database is essential for effective contamination control strategies and can provide valuable insights for investigations.

Insufficient Training of Investigators

Lack of properly trained and competent investigators can significantly impact the quality of contamination investigations. Ensuring that personnel have the necessary skills and knowledge to conduct thorough, science-based investigations is crucial for identifying true root causes and implementing effective corrective actions.

Conclusion

The Sanofi warning letter serves as a reminder of the critical importance of thorough deviation investigations in pharmaceutical manufacturing. By implementing robust investigation and CAPA processes, companies can not only avoid regulatory action but also drive continuous improvement in their operations. This requires ongoing commitment to developing investigator competencies, using structured methods, looking beyond superficial causes, and fostering a culture that values quality and learning from deviations.

As the industry continues to evolve, effective investigation practices will be essential for ensuring product quality, patient safety, and regulatory compliance. By viewing deviations not as failures but as opportunities for improvement, pharmaceutical manufacturers can build more resilient and reliable production systems.