In ASTM E2500, a Subject Matter Expert (SME) is an individual with specialized knowledge and technical understanding of critical aspects of manufacturing systems and equipment. The SME plays a crucial role throughout the project lifecycle, from defining needs to verifying and accepting systems. They are responsible for identifying critical aspects, reviewing system designs, developing verification strategies, and leading quality risk management efforts. SMEs ensure manufacturing systems are designed and verified to meet product quality and patient safety requirements.

In the ASTM E2500 process, the Subject Matter Experts (SME) has several key responsibilities critical to successfully implementing the standard. These responsibilities include:

- Definition of Needs: SMEs define the system’s needs and identify critical aspects that impact product quality and patient safety.

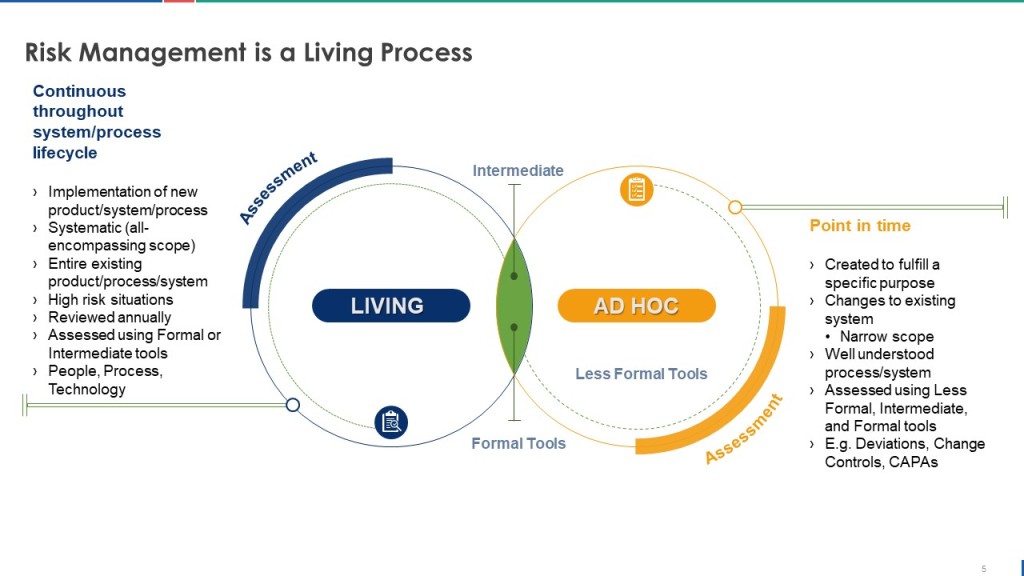

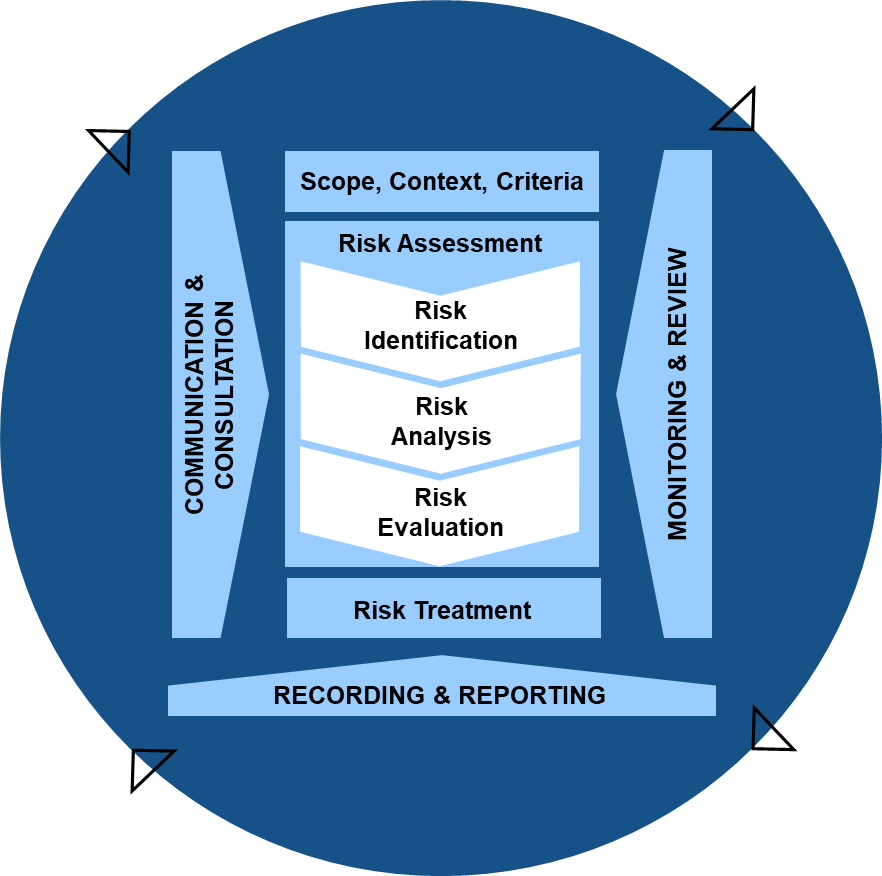

- Risk Management: SMEs participate in risk management activities, helping to identify, assess, and manage risks throughout the project lifecycle. This includes conducting quality risk analyses and consistently applying risk management principles.

- Verification Strategy Development: SMEs are responsible for planning and defining verification strategies. This involves selecting appropriate test methods, defining acceptance criteria, and ensuring that verification activities are aligned with the project’s critical aspects.

- System Design Review: SMEs review system designs to ensure they meet specified requirements and address identified risks. This includes participating in design reviews and providing technical input to optimize system functionality and compliance.

- Execution of Verification Tests: SMEs lead the execution of verification tests, ensuring that tests are conducted accurately and that results are thoroughly reviewed. They may also leverage vendor documentation and test results as part of the verification process, provided the vendor’s quality system and technical capabilities are deemed acceptable.

- Change Management: SMEs play a crucial role in change management, ensuring that any modifications to the system are properly evaluated, documented, and implemented. This helps maintain the system’s validated state and ensures continuous compliance with regulatory requirements.

- Continuous Improvement: SMEs are involved in continuous process improvement efforts, using operational and performance data to identify opportunities for enhancements. They also conduct root-cause analyses of failures and implement technically sound improvements based on gained product knowledge and understanding.

These responsibilities highlight the SME’s integral role in ensuring that manufacturing systems are designed, verified, and maintained to meet the highest standards of quality and safety, as outlined in ASTM E2500.

The ASTM E2500 SME is a Process Owner

ASTM E2500 uses the term SME in the same way we discuss process owners, or what is sometimes called product or molecule stewards. The term should probably be changed to reflect the special role of the SME and the relationship with other stakeholders.

A Molecule Steward has a specialized role within pharmaceutical and biotechnology companies and oversees the lifecycle of a specific molecule or drug product. This role involves a range of responsibilities, including:

- Technical Expertise: Acting as the subject matter expert per ASTM E2500.

- Product Control Strategies: Implementing appropriate product control strategies across development and manufacturing sites based on anticipated needs.

- Lifecycle Management: Providing end-to-end accountability for a given molecule, from development to late-stage lifecycle management.

A Molecule Steward ensures a drug product’s successful development, manufacturing, and lifecycle management, maintaining high standards of quality and compliance throughout the process.

The ASTM E2500 SME (Molecule Steward) and Stakeholders

In the ASTM E2500 approach, the Subject Matter Expert (Molecule Steward) collaborates closely with various project players to ensure the successful implementation of manufacturing systems.

Definition of Needs and Requirements

- Collaboration with Project Teams: SMEs work with project teams from the beginning to define the system’s needs and requirements. This involves identifying critical aspects that impact product quality and patient safety.

- Input from Multiple Departments: SMEs gather input from different departments, including product/process development, engineering, automation, and validation, to ensure that all critical quality attributes (CQAs) and critical process parameters (CPPs) are considered.

Risk Management

- Quality Risk Analysis: SMEs lead the quality risk analysis process, collaborating with QA and other stakeholders to identify and assess risks. This helps focus on critical aspects and consistently apply risk management principles.

- Vendor Collaboration: SMEs often work with vendors to leverage their expertise in conducting risk assessments and ensuring that vendor documentation meets quality requirements.

System Design Review

- Design Review Meetings: SMEs participate in design review meetings with suppliers and project teams to ensure the system design meets the defined needs and critical aspects. This collaborative effort helps in reducing the need for modifications and repeat tests.

- Supplier Engagement: SMEs engage with suppliers to ensure their design solutions are understood and integrated into the project. This includes reviewing supplier documentation and ensuring compliance with regulatory requirements.

Verification Strategy Development

- Developing Verification Plans: SMEs collaborate with QA and engineering teams to develop verification strategies and plans. This involves selecting appropriate test methods, defining acceptance criteria, and ensuring verification activities align with project goals.

- Execution of Verification Tests: SMEs may work with suppliers to conduct verification tests at the supplier’s site, ensuring that tests are performed accurately and efficiently. This collaboration helps achieve the “right test” at the “right time” objective.

Change Management

- Managing Changes: SMEs play a crucial role in the change management process, working with project teams to evaluate, document, and implement changes. This ensures that the system remains in a validated state and continues to meet regulatory requirements.

- Continuous Improvement: SMEs collaborate with other stakeholders to identify opportunities for process improvements and implement changes based on operational and performance data.

Documentation and Communication

- Clear Communication: SMEs ensure clear communication and documentation of all verification activities and acceptance criteria. This involves working closely with QA to validate all critical aspects and ensure compliance with regulatory standards.